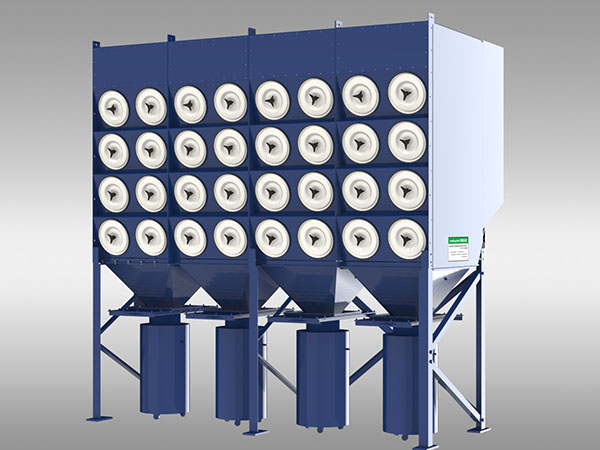

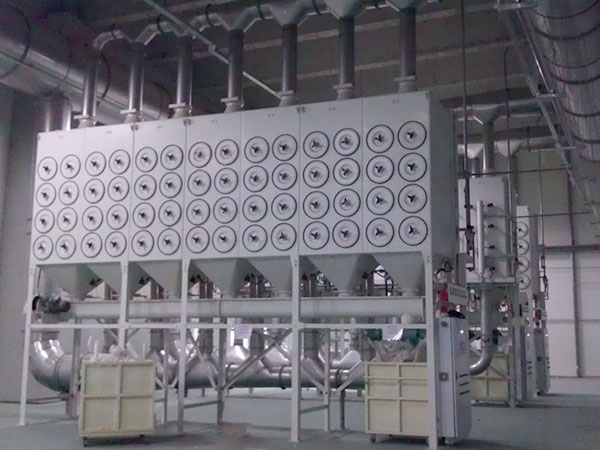

Cartridge Uthuli Collector

Inkcazelo emfutshane:

Isakhiwo sekhatriji esime nkqo sisetyenziselwa ukuququzelela ukufunxa uthuli kunye nokususwa kothuli; kwaye ngenxa yokuba izinto zokucoca zishukuma kancinci ngexesha lokususwa kothuli, ubomi bekhatriji yokucoca bude kakhulu kunobo bengxowa yokucoca, kwaye iindleko zokuyigcina ziphantsi.

Isishwankathelo

Umqokeleli wothuli wodidi lwekhatriji ukwabizwa ngokuba ngumqokeleli wothuli wodidi lwemagazini okanye umqokeleli wothuli wokucoca icartridge. Iimpawu eziphambili zezi zilandelayo:

1.Isakhiwo sekhatriji esime nkqo sisetyenziselwa ukuququzelela ukufunxa uthuli kunye nokususwa kothuli; kwaye ngenxa yokuba izinto zokucoca zishukuma kancinci ngexesha lokususwa kothuli, ubomi bekhatriji yokucoca bude kakhulu kunobo bengxowa yokucoca, kwaye iindleko zokuyigcina ziphantsi.

2.Ukwamkela le ndlela yokucoca yangoku yamazwe ngamazwe ephucukileyo yamazwe amathathu (ukuhluza, ukucocwa, ukushukuma) ukunqanda into ethi "re-adsorption" ngexesha lokucoca, ukwenza ukucoca kuthembeke ngokupheleleyo.

3.Idizayinwe ngendlela yokuqokelela uthuli yangaphambi kothuli, engoyisi kuphela ukusilela kokukhuhla uthuli ngokuthe ngqo kwaye kulula ukuyinxiba i-cartridge yokucoca, kodwa inokunyusa kakhulu ukuxinana kothuli ekungeneni komqokeleli wothuli.

4. Amacandelo angaphandle asetyenziselwa amacandelo abalulekileyo achaphazela ukusebenza okuphambili (njenge-valve ye-pulse), kunye nobomi benkonzo ye-diaphragm yecandelo elisengozini lidlula amaxesha ezigidi ze-1.

5. Ukwamkela iteknoloji yokutshiza kunye nokucoca iteknoloji, enye ivalve ye-pulse inokutshiza umqolo omnye ngexesha elinye (inani leekhatriji zokucoca kumqolo ngamnye ukuya kwi-12), enokunciphisa kakhulu inani leevalve ze-pulse.

6. Indlela yokucoca i-ash ye-tatu yevalve ye-pulse ithatha i-PLC yokulawula ngokuzenzekelayo, kwaye ineendlela ezimbini zokulawula, ixesha okanye incwadi, ukukhetha kuyo.

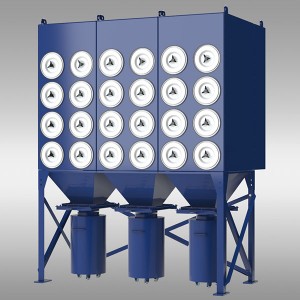

7. Naluphi na udibaniso lweekhatriji zokucoca ezinamanani ahlukeneyo eekholomu kunye nemigqa ingasetyenziselwa ngokweemfuno zendawo yokufaka; isithuba esine-dimensional-dimensional ethathwe yindawo yokucoca iyunithi incinci, enokugcina indawo eninzi yobutyebi kumsebenzisi kwaye inciphise ngokungathanga ngqo iindleko zotyalo-mali lwexesha elinye.

8.Ubomi benkonzo ende, ubomi benkonzo yekhatriji yokucoca inokufikelela kwiminyaka emi-2 ukuya kwemi-3, enciphisa kakhulu inani lamaxesha okucoca umqokeleli wothuli endaweni yawo (isihluzo sengxowa yemveli sitshintshwa rhoqo ngeenyanga ezi-6 ngokwe-avareji), ukugcinwa ilula, kwaye ukugcinwa kuncitshiswe kakhulu. Iindleko zokulondolozwa komsebenzisi ngexesha lokusetyenziswa.

9.Le mveliso isetyenziswa ngokubanzi kuthuli lwemizi-mveliso yentsimbi kunye nesinyithi, ukunyibilikiswa kwe-non-ferrous, isamente yokwakha, ukuphosa koomatshini, ukutya kunye neshishini lokukhanya, ishishini lemichiza yemihla ngemihla, icuba, iidocks zokugcina, iibhoyila zesikhululo samandla, izibiyeli zokufudumeza, kunye nenkunkuma kamasipala. amashishini okutshisa. Ukuhlanjululwa kunye nokulawula.

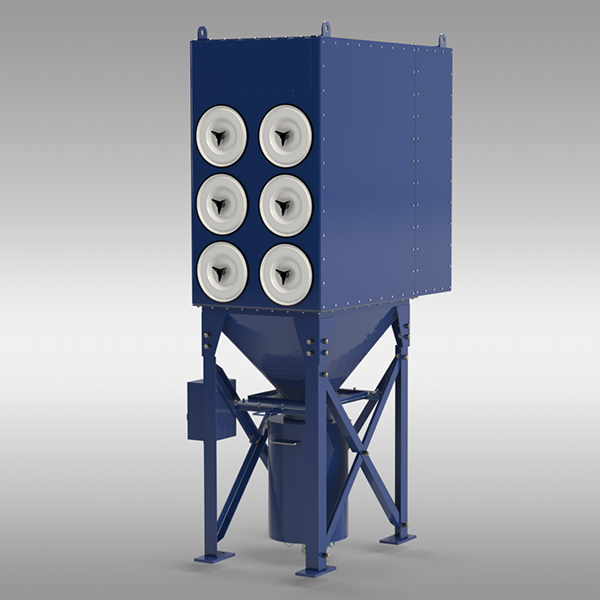

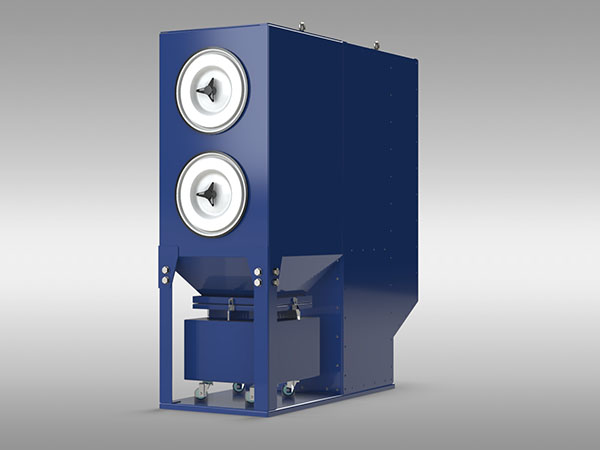

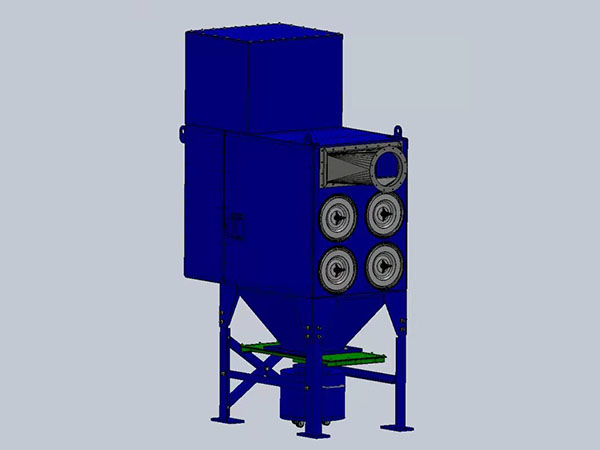

Ulwakhiwo

Umqokeleli wothuli wohlobo lwe-cartridge luqulunqwe ngumbhobho wokungena emoyeni, umbhobho wokukhupha, umzimba webhokisi, i-ash hopper, isixhobo sokucoca umlotha, isixhobo sokuphambukisa, ipleyiti yokuhambisa umoya, i-cartridge yokucoca kunye nesixhobo sokulawula umbane, esifana nebhokisi yomoya i-pulse bag yokususwa kothuli. Ukulungiswa kwekhatriji yokucoca kumqokeleli wothuli kubaluleke kakhulu. Inokulungiswa ngokuthe nkqo phezu kophahla lwekhabhinethi okanye ithotywe phezulu. Ukususela kumbono wesiphumo sokucoca, ukulungelelaniswa ngokuthe nkqo kunengqiqo. Indawo esezantsi yophahla ligumbi lokucoca, kwaye indawo ephezulu yibhokisi yomoya. Ipleyiti yokuhambisa umoya ifakwe ekungeneni komqokeleli wothuli.

Umgaqo wokuSebenza

Emva kokuba igesi equlethe uthuli ingena kwi-hopper yothuli lomqokeleli wothuli, ngenxa yokwandiswa ngokukhawuleza kwe-airflow cross-section kunye nesiphumo sepleyiti yokusabalalisa umoya, inxalenye yamasuntswana arhabaxa ekuhambeni komoya ihlala eluthuthwini. i-hopper phantsi kwesenzo samandla ashukumisayo kunye ne-inertial; i-fine-grained kunye ne-low-density dust particles ingena kwigumbi lokucoca uthuli. Ngeempembelelo ezidibeneyo ze-Brownian diffusion kunye ne-sieving, uthuli lufakwe phezu kwendawo yokucoca, kwaye igesi ecocekileyo ingena kwigumbi lomoya elicocekileyo kwaye ikhutshwe ngumbhobho wokukhupha nge-fan. Ukumelana nesihluzo se-cartridge kuyanda ngokunyuka kobunzima bomaleko wothuli kumphezulu wezinto zokucoca. Coca uthuli xa ukuchasana kufikelela kwixabiso elithile elichaziweyo. Ngeli xesha, inkqubo ye-PLC ilawula ukuvulwa nokuvalwa kwevalve ye-pulse. Okokuqala, ivalve yokunyusela yegumbi elingaphantsi ivalwe ukunqamla ukuhamba komoya okucoca, emva koko kuvulwe ivalve ye-electromagnetic pulse. Umoya ocinezelweyo kunye nexesha elifutshane landiswa ngokukhawuleza kwibhokisi ephezulu kwaye ugalelwe kwi-cartridge yokucoca ukwenza i-cartridge yokucoca Ukwandiswa kunye nokuguqulwa kuvelisa ukungcangcazela, kwaye phantsi kwesenzo sokuhamba komoya ojikelezayo, uthuli olufakwe ngaphandle. Umphezulu wengxowa yokucoca uyaxotyulwa kwaye iwele kwi-ash hopper. Emva kokugqitywa kokususwa kothuli, ivalve ye-electromagnetic pulse ivaliwe, ivalve ye-poppet iyavulwa, kwaye igumbi libuyela kwimeko yokucoca. Ukucoca kuqhutyelwa kwigumbi ngalinye ngokulandelelana, kwaye umjikelezo wokucoca uqala ukusuka ekucoceni kwegumbi lokuqala ukuya ekuqaleni kokucoca okulandelayo. Uthuli oluwileyo luwela kwi-ash hopper kwaye lukhutshwe ngevalve yokuthulula uthuthu.

Inkqubo yokususa uthuli yesihluzi somqokeleli wothuli lwekhatriji kukuqala unqumle umjelo ococekileyo wokuphuma womoya wegumbi elithile, wenze igumbi libe kwindawo engashukumiyo, emva koko wenze i-air pulse back-blowing ukucoca uthuli. imizuzwana embalwa emva kokususwa kothuli Emva kokuhlaliswa kwendalo, umjelo wokuphuma komoya ococekileyo wegumbi uvulwa kwakhona, ongacoci kuphela uthuli ngokupheleleyo, kodwa ugweme ukubhengezwa kwesibini kothuli oluveliswa ngokutshiza kunye. ukucoca, ukwenzela ukuba uthuli lujikelezwe ukusuka kwigumbi ukuya kwelinye.

Ukukhethwa komqokeleli wothuli

1. Ukumiselwa kwesantya somoya wokuhluza

Ukuhluza isantya somoya yenye yeeparamitha eziphambili zokukhethwa kwabaqokeleli bothuli. Kufuneka kumiselwe ngokwendalo, ubungakanani bamasuntswana, ubushushu, ugxininiso kunye nezinye izinto zothuli okanye umsi kwizicelo ezahlukeneyo. Ngokuqhelekileyo, i-concentration yothuli lwe-inlet yi-15-30g / m3. Isantya somoya wokuhluza akufunekanga sibe sikhulu kuno-0.6~0.8m/min; Ugxininiso lothuli olungenayo kufuneka lube yi-5~15g/m3, kwaye isantya somoya sokuhluza akufunekanga sibe sikhulu kuno-0.8~1.2m/min; Ugxininiso lothuli olungenayo kufuneka lube ngaphantsi okanye lulingane ne-5g/m3, kwaye isantya somoya sokuhluza kufuneka singabi ngaphezu kwe-1.5~2m/min. Ngamafutshane, xa ukhetha isantya somoya wokucoca, ukuze unciphise ukuxhathisa kwesixhobo, ngokubanzi isantya somoya wokucoca akufuneki sikhethwe sibe sikhulu kakhulu.

2. Izinto zokuhluza

Isihluzi sekhatriji se-JWST samkela i-PS okanye i-PSU yepolymer egqunywe imathiriyeli yokucoca ifayibha. Xa irhasi ehluziweyo ikwiqondo lobushushu begumbi okanye ingaphantsi kwe-100 ° C, i-PS i-polymer coated fiber filter material isetyenziswa ngokubanzi. Ukuba isetyenziswe kwizicelo zokushisa okuphezulu, kufuneka isetyenziswe. I-PSU polymer coated fiber filter material, ukuba isetyenziswe ngamaxesha aneemfuno ezizodwa, kufuneka ichazwe ngaphambi koku-odola, kwaye izinto zokucoca kufuneka zikhethwe ngokwahlukeneyo.

3.Ifomu yokukhupha uthuthu

Uluhlu lwe-JWST lokucoca ikhatriji abaqokeleli bothuli bonke basebenzisa izikhonkwane zokuhambisa ukukhupha uthuthu (abaqokeleli bothuli bemiqolo 1-5 basebenzisa izinto zokukhupha iinkwenkwezi ukukhupha uthuthu).

Inkqubo yokucoca into yokubuyisela yifeni etsala umoya oqulethe umgubo, iwuhluze ngesihluzo somoya, emva koko isebenzise i-pulse circuit kulawulo oluzenzekelayo. Umgubo ofakwe kwisihluzi somoya ngexesha lokutshiza ngumgubo uya kuBethelwa phantsi ngoxinzelelo oluphezulu lomoya.

Imodeli yemveliso

I-JT-LT-4

I-JT-LT-8

I-JT-LT-12

I-JT-LT-18

I-JT-LT-24

I-JT-LT-32

I-JT-LT-36

I-JT-LT-48

I-JT-LT-60

I-JT-LT-64

I-JT-LT-112

I-JT-LT-160